Business partner for success of clients!

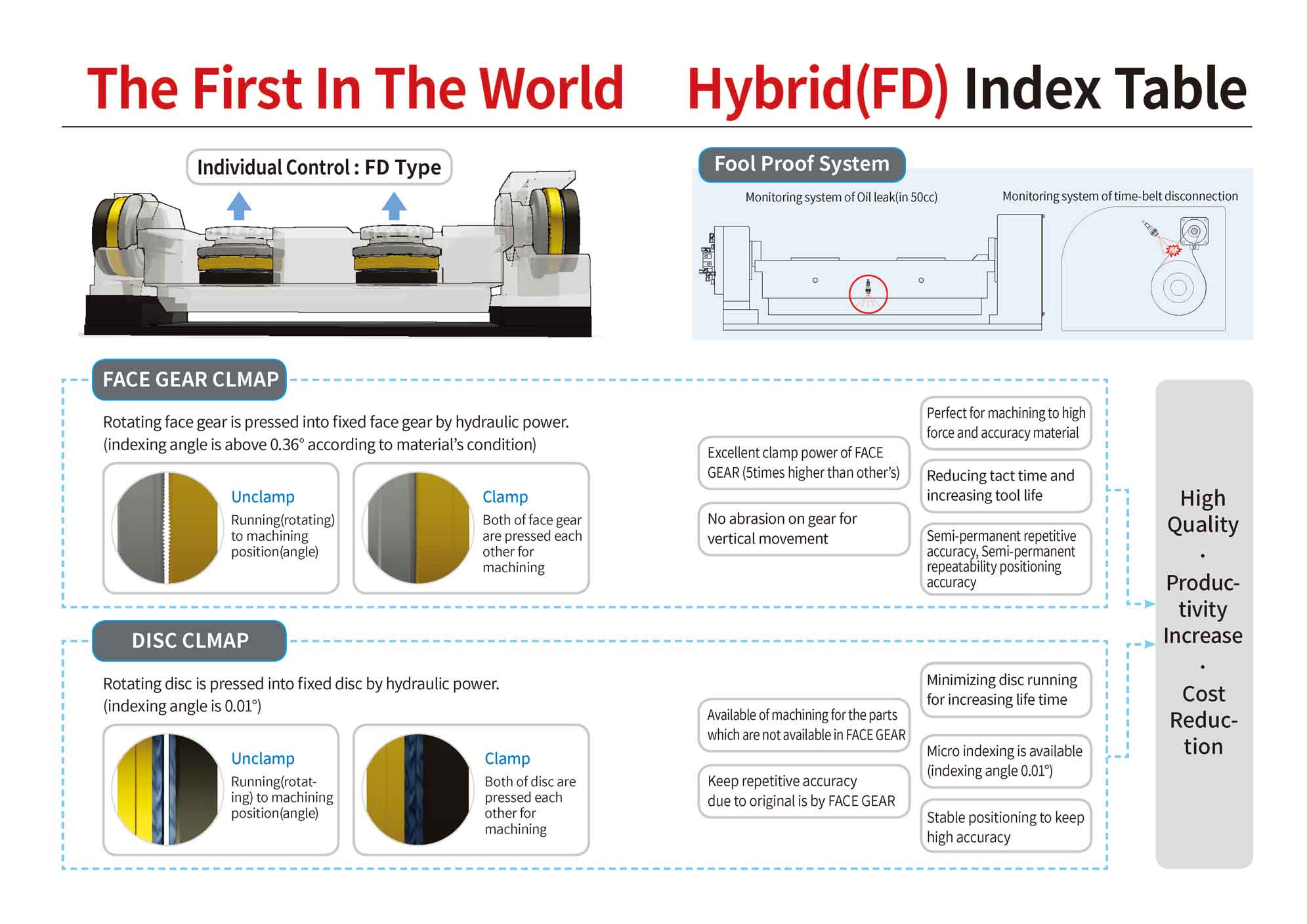

Face gear division angle method allows high cutting without shaking – Utility Design no. 20-0456169

Face gear division angle method allows high cutting without shaking – Utility Design no. 20-0456169

Index Division

Contact Us

daeshin32@nate.com

Send an e-mail and we’ll answer right away

CUSTOMER

DAESHINHITEC Co.,Ltd

Index Division

DAESHINMACHINE Co.

Automobile Division